Why should we go to PumpAir Solutions when products can be bought directly from manufacturers?

PumpAir Solutions are independent consultants and suppliers with decades of knowledge on Blower, Vacuum pumps and Compressor products. We do not push any brand/make and only recommend product that is best suited for the application. As we have access to competitive products, we can offer very good prices.

What are different technologies in blowers suited for sewage treatment plants?

Different technologies are available world wide depending on size of treatment plant and whether it is domestic or commercial waste water treatment plant. We can offer complete product range for Commercial, semi commercial and domestic waste water treatment systems. We can offer multistage blowers, single stage roots type blowers, side channel blowers and diaphragm or piston type blowers.

In Australia diaphragm type domestic sewage blowers available from Gardner Denver Thomas Yasunaga and Hiblow are prominent. Piston type of air blower for Aerated waste water system is available is from Nitto Kohki.

What Models of Septic tank blowers can you offer?

PumpAir Solutions have access to Gardner Denver Thomas Yasunaga Septic blowers Model LP60A, AP80,AP80H,LP80HN,LP100H,LP120H,LP150H and LP200H blowers and Hiblow Models HP60, XP80,HP80,HP120,HP150 and HP200. We can also offer Nitto piston Blower Model LA 80B.

What parts are normally needed for servicing of Thomas, Hiblow and Nitto blowers?

For diaphragm blowers, normally major repair kit consisting of Chamber blocks, inlet filter, inlet filter gasket and tank gasket are required. We stock these parts which are These are sold as a kit but can be bought as individual parts as well.

For Nitto piston blowers repair kit consists of piston kit and filter.

Why do blowers normally fail and precautions to be taken to get better life out of blowers?

Normal regular maintenance is very critical for longer life of blowers. Inlet filters need to be cleaned regularly and adequate ventilation of blower is essential to achieve good life span.

While installing the blower and during maintenance it is essential to check back pressure on the system. Excessive or low back pressure can result in failure of diaphragm or overheating of blower resulting in failure. The back pressure figures are available for various blower models.

For Nitto piston type blowers, regular greasing and changing of inlet filter will result in better life.

What are the warranty/return conditions on my purchase?

Warranty for Septic tank blowers is standard manufacturer’s warranty and we ensure all warranty claims are settled amicably with our customers.

Should I contact PumpAir Solutions or the manufacturer regarding warranty?

All warranty issues are to be referred to us first and we will take up with the manufacturer. If different conditions apply, we will be able to advise you on the best course of action.

Do you sell Aerators also for septic tanks?

Thomas Yasunaga, Hiblow( Pumpserv) and Nitto blowers sold by us are commonly also known as Aerators, septic tank aerators, Septic tank blowers etc. Hiblow and Thomas blowers are diaphragm blowers/Linear Air blowers whereas Nitto/Medo blowers are Piston type blowers and all are used in domestic waste water or Aerated waste water systems.

What methods of payment do you accept?

We accept payment via credit card over the phone, cheque, cash or by direct deposit into our account. Please phone for details.

What is my expected turnaround on orders?

We generally stock the blowers and repair kits. The standard turnaround time is generally 1-2 working days from date of order confirmation.

We endeavor to supply the parts against the order the same day and send confirmation email towards delivery of each consignment.

What methods of shipping do you use?

We have many different options available for shipping. We generally use Fastway Couriers for confirmation of delivery and Australia post satchels for smaller items. Items can be sent registered, express or standard freight. We assess each order individually to ensure that most cost effective means of delivery is used.

Should I contact Air Dimensions or the manufacturer regarding warranty?

All warranty issues are to be referred to us first and we will take up with the manufacturer. If different conditions apply, we will be able to advise you on the best course of action.

What Parts of Thomas Yasunaga Septic Blowers do you stock ?

We stock all parts of Rietschle Thomas Yasunaga Septic blowers Model LP60A, LP80HN, LP100H, LP120H, LP150H and LP200H blowers .Mostly chamber block kit, Major repair kit, tank gasket and inlet filter gasket are required. Major repair kit comprises of two chamber block diaphragms, inlet filter, inlet filter gasket and tank gasket.

What Parts of Techno Takasuki Hiblow septic aerators do you stock ?

We stock PumpServ Hiblow Models HP60, HP80, HP120, HP150 and HP200. The new introduction Model XP80 is also available. We carry Diaphragm kits, diaphragm in their surrounds, base gasket and chamber block kit for these septic air pumps.

What Parts of Nitto Septic Blowers do you stock ?

We stock piston kit for Nitto La80B and LA120 blowers.

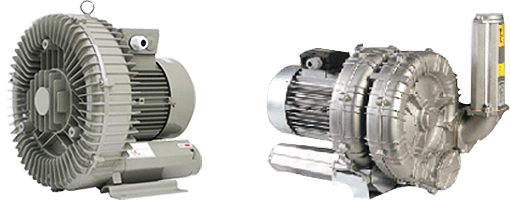

What other type of blowers do you sell ?

We sell Linear Air Blowers, Gardner Denver side channel blowers, FPZ side channel blowers, Gardner Denver Sutorbilt roots blowers and Pedro Gil Roots blowers. So a complete range of blowers for water, waste water and sewage treatment are available through PumpAir solutions.

What is Anaerobic digestion?

Anaerobic digestion is a bacterial process that is carried out in the absence of oxygen. The process can either be

thermophilic digestion, in which sludge is

fermented in tanks at a temperature of 55°C, or

mesophilic, at a temperature of around 36°C. Though allowing shorter retention time (and thus smaller tanks), thermophilic digestion is more expensive in terms of energy consumption for heating the sludge.

Anaerobic digestion is the most common (mesophilic) treatment of domestic sewage in septic tanks, which normally retain the sewage from one day to two days, reducing the BOD by about 35 to 40 percent. This reduction can be increased with a combination of anaerobic and aerobic treatment by installing

Aerobic Treatment Units (ATUs) in the septic tank.

One major feature of anaerobic digestion is the production of

biogas (with the most useful component being

methane), which can be used in generators for electricity production and/or in boilers for heating purposes.

What is Aerobic digestion?

Aerobic digestion is a bacterial process occurring in the presence of oxygen. Under aerobic conditions, bacteria rapidly consume organic matter and convert it into

carbon dioxide. The operating costs used to be characteristically much greater for aerobic digestion because of the energy used by the blowers, pumps and motors needed to add oxygen to the process.

Aerobic digestion can also be achieved by using

diffuser systems or

jet aerators to oxidize the sludge. Fine bubble diffusers are typically the more cost-efficient diffusion method, however, plugging is typically a problem due to sediment settling into the smaller air holes. Coarse bubble diffusers are more commonly used in activated sludge tanks (generally a side process in waste water management) or in the flocculation stages. A key component for selecting diffuser type is to ensure it will produce the required oxygen transfer rate.

What is Aerated Wastewater Treatment Systems (AWTS)

In unsewered areas, the proper treatment and utilisation of household wastewater on-site is critical in preserving the health of the public and the environment. AWTS’s have been developed as a way of achieving this.

In Australia there are many manufacturers of AWTS systems like Envirocycle, Econocycle, Bioseptic, Biocycle, Taylex, Fujiclean and Enviro-septic etc.They all have different designs of tanks etc but use Septic blowers of Hiblow, Gardner Denver Thomas and Nitto Kohki.

What is Domestic Sewage Treatment - Black & Grey Water ?

Domestic Systems are often referred to as ‘On-site Systems’ because the treated waste water has to be discharged within the site or property the waste water is generated. Systems are required where municipal services aren’t available. Other terms used to describe domestic systems are AWTS, HTPS systems or traditionally septic systems. The system names are based around the treatment process used by the system. Systems available to consumers are required to complete Australian Standards certification testing followed by approval in each state to supply and install. The permitted uses of the treated water are governed by local council, the most common approved methods include surface heavy drop sprinklers, surface and subsurface dripper systems and in some cases trenching is still required. The steps in the process of installing a domestic wastewater treatment system are in most cases as follows.

An AWTS does the job normally handled by a large Sewage Treatment Plant. Instead of occupying large tracts of public land, it is a purpose built system used for the treatment of sewerage and liquid wastes from a single household or multiple dwellings.

It consists of a series of treatment chambers combined with an irrigation system. An AWTS enables people living in unsewered areas to treat and utilise their wastewater.

How does an AWTS work?

All water borne wastes from kitchen, laundry, bathrooms and toilets are treated in stages in several separate chambers. The first chamber is similar to a conventional septic tank. The wastewater enters the chamber where in the absence of oxygen (anaerobic) bacteria which thrive in these conditions reduce the toxicity of wastes. The solids settle to the bottom and are retained in the tank forming a sludge layer. Scum collects at the top, and the partially treated wastewater flows into a second chamber.

This treatment process consists of four stages

- Aerobic digestion

- Disinfection

- Final clarification

- Sand filtration

The aerobic digestion stage uses aeration and biological media to remove the organic material from the wastewater. The final clarification stage allows remaining solids to be removed from the treated water before moving into the disinfection stage. The disinfection kills harmful bacteria in the wastewater. This is then passed through a sand filter which polishes the wastewater and makes it useable for your garden and plants.

In the primary stage, treatment is anaerobic, where bacteria thrive in an oxygen free zone, and the breakdown of solid waste is performed. From here the waste is sent to the second stage where air is continually supplied to bacteria providing aerobic treatment to complete the total digestion process.

At this point the wastewater passes through a clarifying process into the disinfection chamber where any remaining pathogenic bacteria are destroyed. Finally the now clean, clear and disinfected water is delivered by an integral submersible pump with automatic level control to a selected irrigation system in the landscaped garden beds or other dispersion areas.

Bacteria in the first chamber break down the solid matter in the sludge and scum layers. Materials that cannot be fully broken down gradually build up in the chamber and must be pumped out periodically.