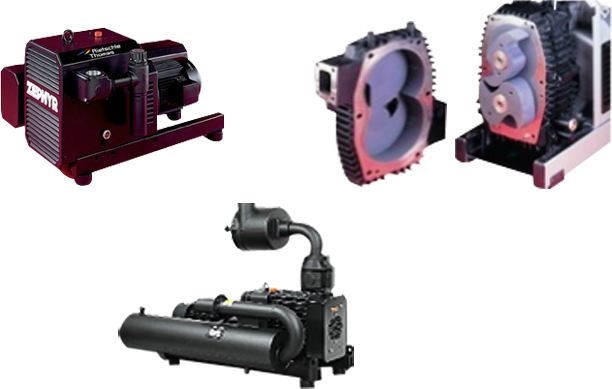

Dry Running Claw Vacuum Pumps and Compressors:

Gardner Denver and Elmo Rietschle are well-known for manufacturing dry-running claw vacuum pumps that have a contact-free vacuum or compressed air. They are effective and affordable machinery that uses the rotating claw design and the internal compression concept. An enormous amount of energy is saved by pre-compressing the gas in the compressing chamber before it is discharged.

Our latest dry-running vacuum pump offers much higher efficiency and performance as compared to conventional rotary lobe blower designs that do not have an internal compression mechanism. Furthermore, our advanced sound engineering technology helps to reduce noise levels.

These dry-running claw vacuum pumps have a special design that gives the claws an optimized, high-precision shape so that they run together with one another without making contact. They are further synchronized with the help of a precise gear set that allows dry and wear-free compression.

Special seals are used to keep the gearbox and compression chamber isolated. As the rotor claws regulate the flow of the medium by opening and closing the inlet and outlet channels, there is no need for a sealing fluid inside the chamber.

The inbuilt frequency converters of a dry-running vacuum pump ensure legal compliance and cost-effective operation that meets the legal requirements and lowers the overall operational expenses as well.

Special Features Of Dry Running Claw Vacuum Pumps